Tungsten Cobalt composite Powder Price, Tungsten Carbide Cobalt Powder Suppliers

Coercivity

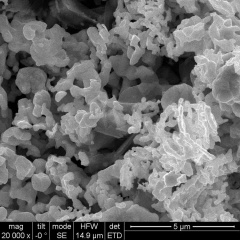

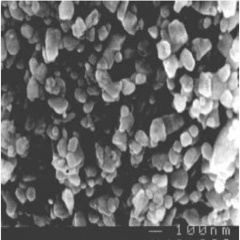

Coercivity tungsten carbide-cobalt alloy due to the binder phase is ferromagnetic material, thus making the alloy has a certain magnetism, the coercive force can be used to control the microstructure of the alloy is an internal tungsten steel manufacturer refers to the occasion . Coercivity WC-Co alloy is mainly concerned with the diamond content and degree of dispersion, with lower cobalt content increases. When a certain amount of cobalt, since the degree of dispersion of cobalt with tungsten carbide grain phase of thinning and improved, so that the coercive force increases. On the contrary, the coercive force is reduced. Therefore, under the same other conditions, the coercive force can be used as parameters of tungsten carbide grain size of the alloy indirect measure: normal tissues in the alloy, with the lower carbon content, increasing the drilling phase of the tungsten content, cobalt phase subject to greater strengthening, the coercive force will therefore increase. Thus, the greater the cooling rate during the sintering, the coercive force is also greater.

Magnetic saturation

Alloy samples in touch field, with increasing applied magnetic field, magnetic induction strength of the alloy increases, when the magnetic field strength reaches a certain value, the magnetic flux density does not increase, that the alloy has reached magnetic saturation. Alloy magnetic saturation value is only related to the amount of the alloy containing a diamond, regardless of the grain size of the tungsten carbide phase alloys. Thus, a non-magnetic phase alloy ηl magnetically saturated alloys can be used for non-destructive inspection of the component, or to identify the presence or absence of known composition.

Elastic Modulus

Since the tungsten carbide has a high elastic modulus, and therefore, WC-Co alloy has a high elastic grinding amount. With the increase in the cobalt content of the alloy, the elastic modulus decreased; tungsten carbide alloy grain size had no significant effect on the elastic modulus. As the temperature rises, the elastic modulus of the alloy decreases.

Thermal conductivity

To avoid tool damage due to overheating during use is generally desirable alloy has a higher thermal conductivity. WC-Co alloy has a higher thermal conductivity of about 0.14-0.21 cal / cm · sec · deg, the thermal conductivity of the alloy cobalt content is generally only related with the decrease of the cobalt content increases.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917