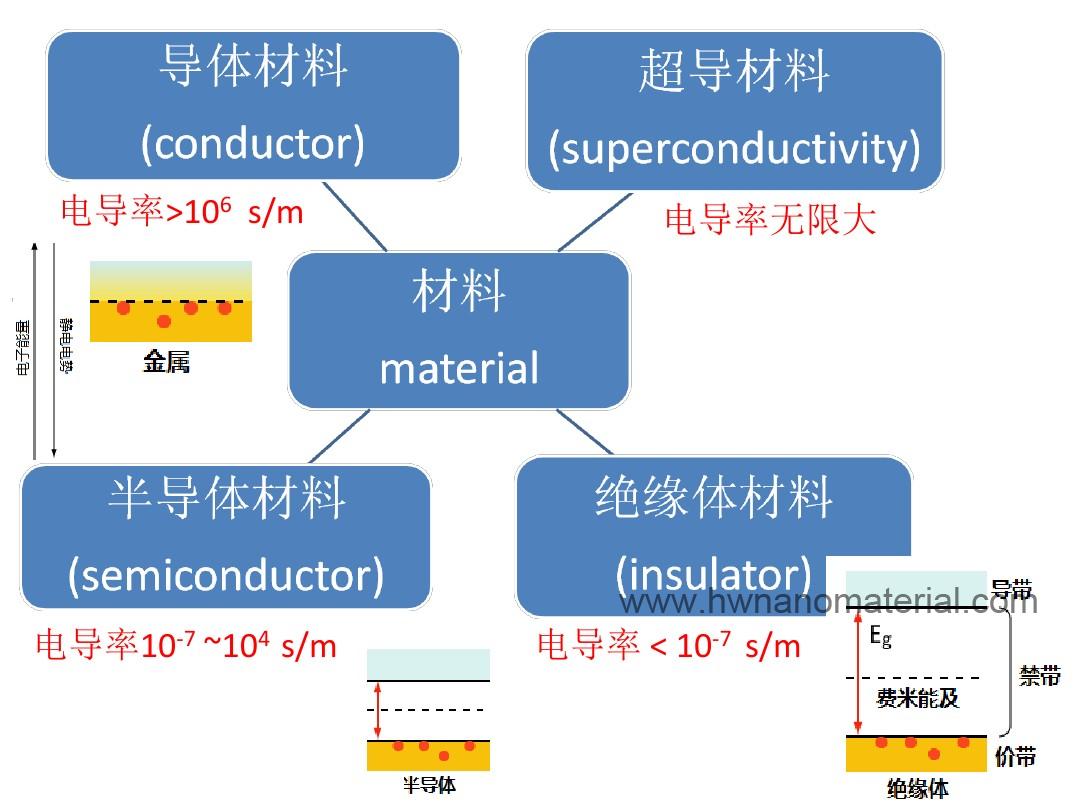

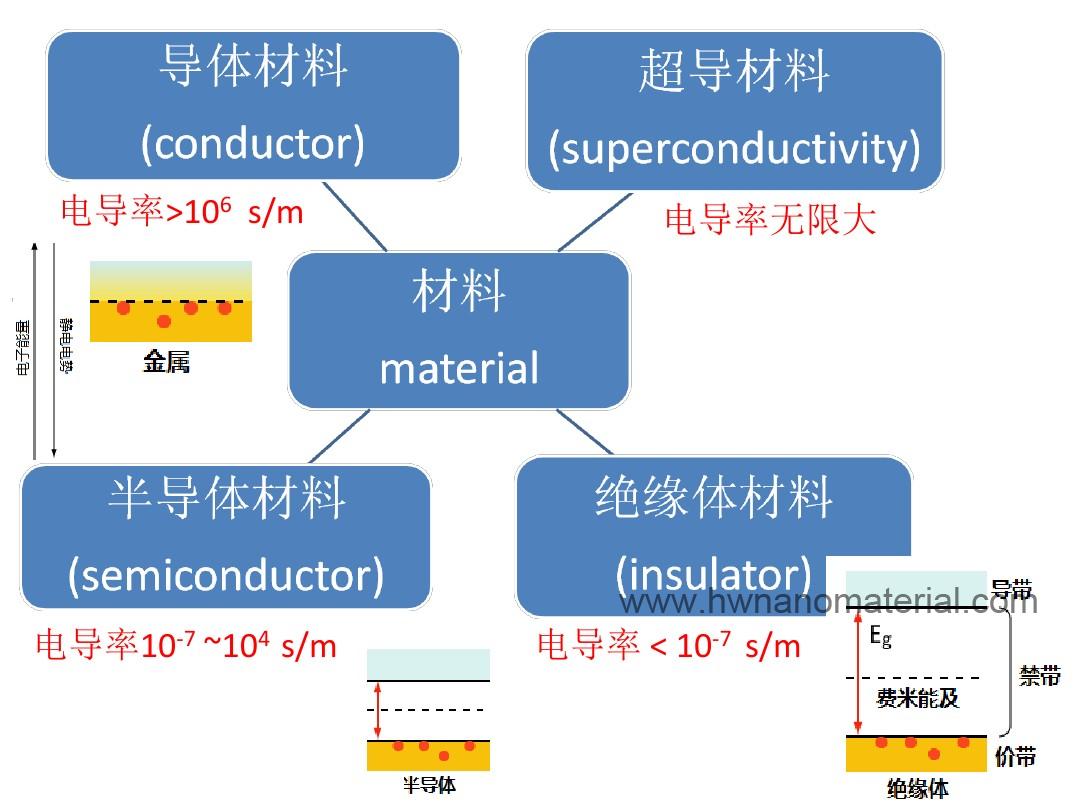

A conductive material is one that has a large number of charged particles that can move freely under the action of an electric field and therefore can conduct current well including conductor materials and superconducting materials.

1. Pure silver conductive powder (Ag99.99%)

1) flake:

Common particle size: <1um, 1-3um, 3-5um, 5-8um, 10um, particle size distribution and bulk density can be customized according to requirements. Available in flaky silver powder with Low bulk density.

Appearance: silver gray with metallic luster

Application: flake silver powder is a high performance conductive filler with good oxidation resistance.Flake silver powder is the main raw material for making conductive coating, film switch, conductive ink, conductive rubber, conductive plastic, conductive ceramics, etc.

Flake silver powder is an ideal raw material for low temperature polymer slurry, conductive paint, conductive paint and electromagnetic shielding paint.The coating prepared with flake silver powder has good fluidity, anti-settling and large spraying area.

2) Spherical:

Common used particle size: <1um, 1-3um, 3-5um, 5-8um, 10um, particle size and parameters can be customized according to requirements.

Application: near-spherical silver powder is mainly suitable for conducting filler of high-temperature sintered conductor paste.

There is no absolute standard for silver powder to be used as a conductive filler. The choice of silver powder should be based on the corresponding adhesive, the public welfare of the target conductor material, the physical and chemical properties of the film layer and the reliability requirements.

2. Silver copper conductive powder

(frequently used particle size 1-3um, 3-5um, 5-8um, 10um, Ag content ranging from 3% to 35%)

Features:

1) silver coated copper powder has small particle size up to submicron level.

2) the morphology of silver-clad copper powder is various, including spherical, flake and dendritic.

3) silver-coated copper powder has excellent electrical conductivity and lower cost, which can replace some application fields of silver powder.

4) silver-coated copper powder has good oxidation resistance and dispersibility, and can be used in medium and low temperature slurry.

Application: it can be widely used in conductive adhesive, conductive coating, polymer slurry, and all kinds of microelectronic technology fields, electromagnetic shielding, non-conductive material surface metallization processing, etc.

Silver-coated copper powder can be widely used in conductive adhesives, conductive coatings, polymer slurry, and all kinds of conductive, conductive electrostatic and other needs of the microelectronic technology field, non-conductive material surface metallization processing industry, is a new type of conductive composite powder.

It widely used in electronics, electromechanical, communications, printing, aerospace, military and other industries of electricity, electromagnetic shielding field.Such as computers, mobile phones, integrated circuits, all kinds of electrical appliances, electronic medical equipment, electronic instruments and meters, so that the products are not subject to electromagnetic interference, at the same time reduce the harm caused by electromagnetic radiation to the human body, as well as colloids, circuit boards, and other insulation conductive processing, so that the insulation of the object has a good conductive performance.

3. The pure copper conductive powder

Frequently particle size: <1um,1-2um,5-8um, etc.

Features: spherical shape, uniform particle size, good dispersion, high crystallinity.

Application: terminal and internal electrode for multilayer ceramic capacitor, electronic component and electronic paste, etc.

4. Pure nickel conductive powder

Frequently particle size: 1-3um

RoHS of nickel powder is available.

Nickel powder, as a kind of functional conductive filler, is added to coating, adhesive, ink, plastic and rubber to make conductive, electromagnetic shielding and anti-static products. It is widely used in the fields of conductive, electromagnetic shielding and anti-static in various industrial sectors such as electronics, electromechanical, communication, printing, aerospace and weapons.Such as computers, mobile phones, electronic medical equipment, electronic instruments and meters and other electronic, electrical, communication products electromagnetic shielding, anti-static.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917