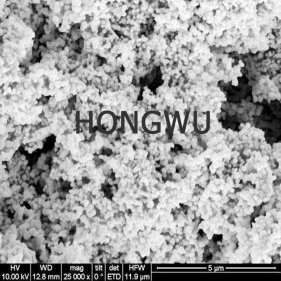

Spherical Zinc Oxide ZNO Nanostructures Application

Spherical Zinc Oxide ZNO Nanostructures Application

Compared with ordinary zinc oxide, Zinc Oxide ZNO Nanostructures has many other excellent performance. At present the main application areas are rubber products, high-grade paint, ink and paint, sunscreen and anti-ultraviolet fabric, sewage treatment,etc.

1. Zinc Oxide ZNO Nanostructures in Rubber Industry

ZnO nanopowder is the most effective inorganic active agent and vulcanization accelerator in rubber industry.

Zinc Oxide ZNO Nanostructures with small particle size 20-30nm, larege specific surface area, good dispersion, loose, porous, good liquidity and good affinity with rubber, easily dispersed whilc melting, low heat plastic material, breaking small deformation , good elasticity, can improve the material process performance and physical properties, thus it's used in the manufacture of high-speed wear-resistant rubber products, such as aircraft tires, high-class passenger car radial tire, with performance of anti-aging, anti-friction fire, long life, and greatly improves finish, mechanical strength, temperature and aging resistance of rubber products,especially wear resistance.

In addition, Zinc Oxide nano as a vulcanization system in the rubber system, whose additive is high.The large specific gravity and filling amount of ordinary ZnO, whose influence on its material density, product life and energy consumption is detrimental. However, the use of Nano grade Zinc Oxide, the amountis only 30% -50% compared to the ordinary one,which reduces the cost of production, and the performance in the tensile properties, heat, aging, etc are far superior to ordinary zinc oxide powder.

2. Zinc Oxide ZNO Nanostructures in Ceramic industry

Because of very small particle size, large specific surface area and high chemical properties,nano ZnO can significantly lower the sintering densification of materials, save energy, make the ceramic material composition densification, homogenization, improve the performance of ceramic materials, the reliability of its use. Controling the composition and structure of materials on the structural level of nano materials is conducive to give full potential performance of ceramic materials. In addition, because the particle size of ceramic material determines the microstructure and macroscopic properties of ceramic materials, if the particles of the powders are uniformly packed and the sintering shrinkage is uniform and the grain grows uniformly, then the smaller the particle size, the smaller the resulting defects, and the higher the strength of the prepared material, which may result in some unique performance that large particles do not have.

3. Nano Zinc Oxide in Other Areas

With the deepening understanding of the performance of nano Zinc Oxide, its applications continue to expand, for example, in the traditional coating technology, adding nano ZnO can further improve the protective capacity, making resistance to atmospheric damage and anti-degradation, color,etc.With a certain percentage of Zinc Oxide nanopowder added to the propionic acid coating, it can be made into excellent nano antibacterial coating. Making use of the sensitive properties of nano ZnO, can produce a high sensitivity gas alarm and hygrometer.

As a new type of semiconductor materials, Zinc Oxide ZNO Nanostructures has become a new type of high-performance fine inorganic products in the 21st century. At present, researchers at home and abroad have developed a variety of methods to prepare various forms of nano zinc oxide products and achieve a lot. However, there are still some shortcomings such as high cost, complicated process and difficulty of industrialization in the preparation method. In addition, the research on the structure and application performance of nano ZnO is not deep, so the follow-up research will focus on the development of simple, high-efficient and easy industrial production methods. With the further study of the material structure on its optical, electrical, magnetic and acoustic properties, it is expected that with the continuous improvement of the preparation method of nano zinc oxide, the nano-size effect of nano-sized oxides, and the study will have a full-speed development stage.

by Jemma

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917