Because of the excellent magnetic, electrical, optical and catalytic properties, nano materials have become a research hotspot in the field of materials in recent years. The application of nano-materials for energy, especially in the field of lithium-ion batteries, can greatly improve the electrochemical performance of materials. Tin particles have a lower melting point and higher lithium storage capacity at the nanoscale, which makes nano tin(Sn) powder have great application prospects in inkjet printing, nano-lead-free solder, and lithium-ion battery electrodes.

|

Name

|

Formula

|

CAS Number

|

Size

|

Purity

|

|

Nano Tin Particles

|

Sn

|

7440-31-5

|

50nm, 70nm,100nm, 200nm

|

99.9%

|

|

Colour

|

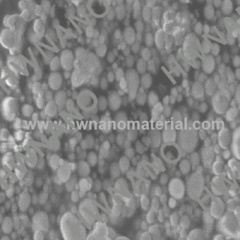

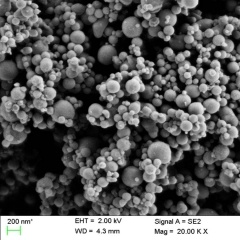

Morphology

|

SSA(m2/g)

|

Delivery time

|

Packing

|

|

black

|

Spherical

|

5.5-7.8

|

in stock for small order

and discuss in bulk

|

25g, 50g, 100g

in double layer anti-stsatic bags.

|

Preparation methods of nano Tin particles: Liquid phase chemical reduction method and Plasma method.

Chemical reduction method: the raw materials used are stannous chloride, PVP, sodium borohydride, and ethanol.

Plasma method: use the high-frequency power supply discharge to generate plasma arc as the heat source, vaporize and evaporate metal tin, and then cool and condense through the collector to generate nano metal Sn powder. Due to the large output of nano-metal powder prepared by plasma method, easy control of particle size, good powder performance, etc., have been widely used in industry.

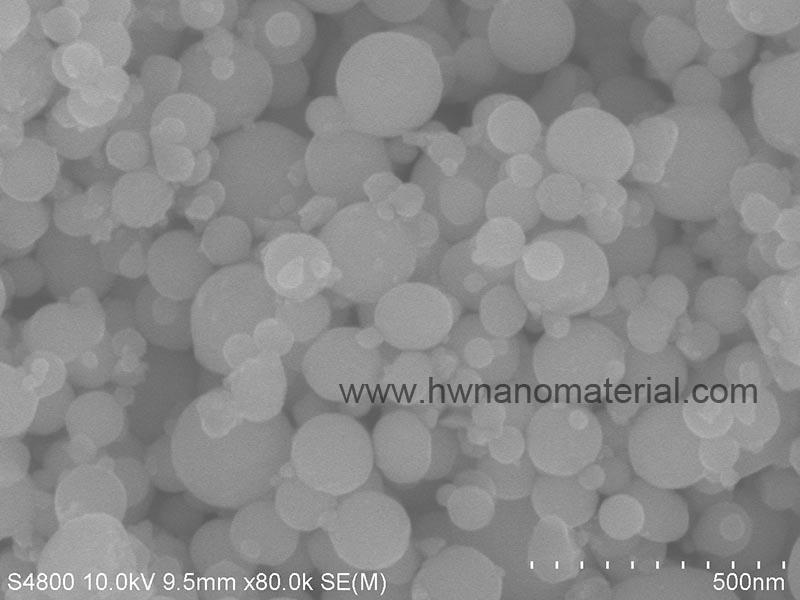

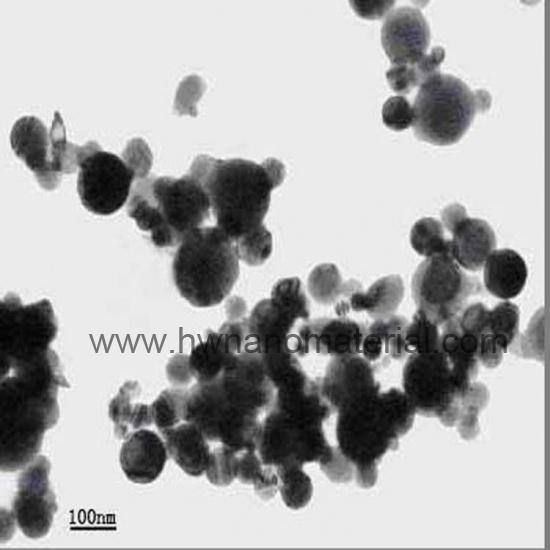

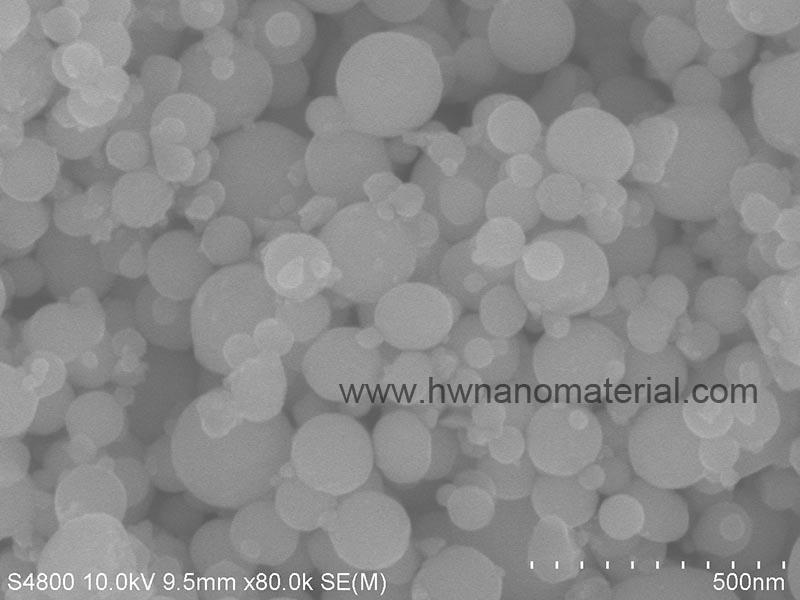

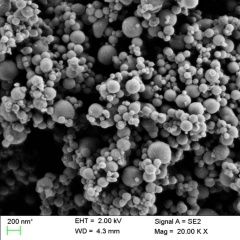

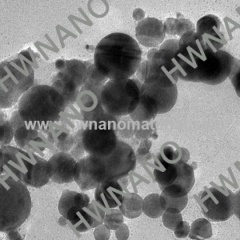

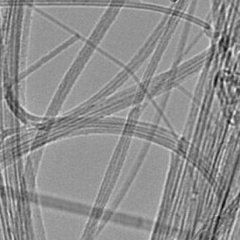

How to check the particle size of nano tin powders: as the particle size of nano tin particles is too small, it is difficult to use conventional powder particle size analysis methods such as laser diffraction method, sedimentation method, sieving method, etc. to characterize the particle size distribution of the powder. General electron microscope observation can intuitively see the particle size distribution, morphology and dispersion state of tin nanoparticles.

What are the common materials related to nano-tin?

Binary alloys such as tin: nano silver tin (Ag-Sn) alloy particles, nano tin bismuth (Sn-Bi) alloy powder (low melting point alloy), nano copper tin (Sn-Cu) alloy; oxides: 10-50nm dioxide Tin (SnO2).

Several applications of nano Tin particles(Sn) are as follows:

1. Lubricating additives: disperse Sn nano evenly in lubricating oils and greases in an appropriate way to obtain multifunctional oil additives with specific properties. The ultrafine particles in it combine with the lubricated solid surface (such as automobile engine, etc.) to form a self-lubricating and self-repairing film on the surface of the friction pair during the friction process, which significantly reduces the anti-wear and anti-friction performance of the friction pair. When Sn nano particles are used as lubricating oil additives, nano Sn particles exhibit good anti-friction and anti-wear properties, which can effectively increase the failure load of base oil.

2. Sintering additives: nano tin particles can greatly reduce the sintering temperature of powder metallurgy products and high-temperature ceramic products in powder metallurgy. At the nanoscale, the melting point of metal particles will decrease as the particle size decreases. Therefore, nano-metal materials have shown great application prospects in the fields of low-temperature sintering and electronic packaging, and their proportions are increasing.

3. Lithium-ion battery anode material: nano tin particles Sn has a high theoretical capacity (for example, 994mah/g), and tin-based anode material is considered to be one of the ideal substitutes for commercial graphite-like carbon materials (372mah/g) to meet the following a generation of high-capacity lithium-ion battery needs.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917