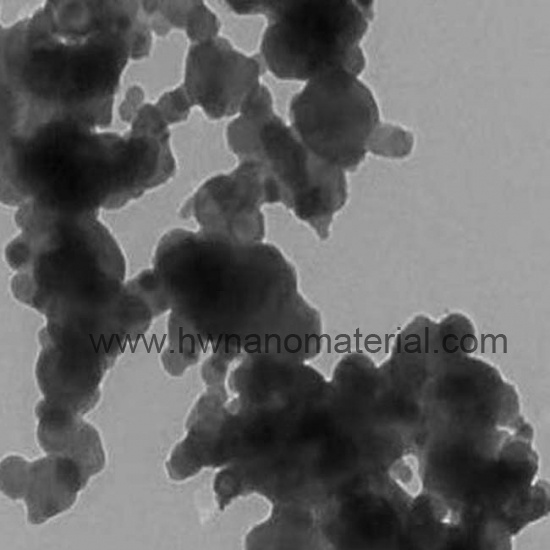

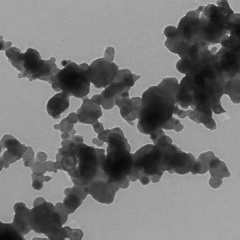

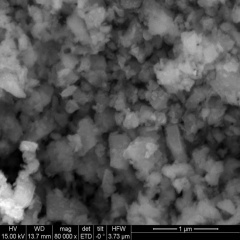

Superhard Titanium Carbide Nanopowder As Ceramic Reinforcing Materials

Spec: 40-60nm, 99%,we could also do micron size titanium carbide powder.

Characteristic of titanium carbide nanopowder:

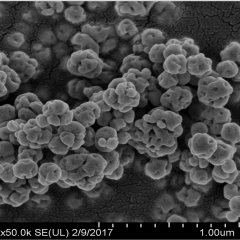

1. Nano-titanium carbide, small particle

size, distribution, large surface area, high surface activity, high

temperature, anti-oxidation, high hardness, is a good refractory wear-resistant

material, is widely used to carbide, superhard wear-resistant material above;

2. The nano titanium carbide has good

electrical conductivity, it can be used as the molten salt electrolysis

electrode material and conductive electrical contacts;

3. Add one ten thousandth of nanometer

titanium carbide can be reduced by titanium carbide ceramic sintering

temperature of 200 degrees, and can refine the grain, improve the sintering

properties;

4. Nano titanium carbide reinforcing phases

can be used as a ceramic material, a metal effective to improve the mechanical

properties of ceramic matrix material and conductive properties.

Application of titanium carbide nanopowder:

1 nanometer titanium carbide used in

aerospace components: Considering the refractory carbide nano TiC, ZrC having a

melting point above3000 ℃,

with excellent high temperature strength, and good compatibility with tungsten,

thermal expansion coefficients are similar, and has more than Tungsten much

lower density. The composite peculiar temperature strength due W substrate

temperature increased from brittleness into the plastic, so that nano TiC and

ZrC particles at high temperature to enhance the role of the plastic W matrix

even more significantly, resulting in composites with excellent high

temperature strength, The nano-particles of TiC particles W NONSTOICHIOMETRIC

ZrC matrix have better high temperature enhancement;

2 nm titanium carbide ceramic foam: foam

ceramics as a filter for a variety of fluid inclusions can be effectively

removed, the filtration and adsorption mechanism is agitation. Filter material

requirements chemical stability, especially in the metallurgical industry is

using the filter requires a high melting point, so the majority of such

materials as oxides, but also to adapt to the molten metal filter, the main

pursuit to improve the thermal shock resistance. Nano-titanium carbide ceramic

foam has a higher strength, hardness, thermal conductivity, electrical

conductivity and heat and corrosion resistance than the oxide ceramic foam;

3 is widely used in manufacturing

wear-resistant materials, cutting tools, dies, metal melting crucibles and

other areas transparent titanium carbide ceramics is a good optical material;

titanium carbide abrasives and abrasive abrasive industry is an alternative to

aluminum oxide, silicon carbide, boron carbide, traditional ideal material for

chromium oxide abrasive material; nano-titanium carbide abrasive materials,

abrasive wheel and ointment products can greatly improve the grinding

efficiency and grinding accuracy and surface finish.

4 PM areas: nano titanium carbide powder

used in powder metallurgy production of ceramics, cemented carbide parts of raw

materials, such as drawing dies, carbide tooling. Nano-titanium carbide-based

alloy has the following characteristics: (1) high hardness, generally up HRA90

above; (2) good wear resistance, low wear rate; (3) good heat and oxidation

resistance; (4) good thermal conductivity, good chemical stability.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917