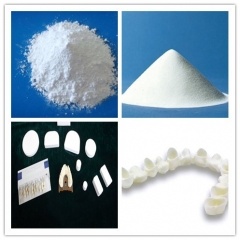

Yttria Stabilized Zirconia powder(8YSZ) oxygen measuring device used in coal-fired power plants

An important task of coal-fired power plants is optimize combustion,namely,to improve the boiler efficiency, reduce the coal consumption, energy conservation. which requires timely and accurate on-line monitoring to the combustion parameters. flue gas oxygen content online detection technology is based on the principle of zirconia solid electrolyte oxygen measurement, analyze various the external and internal factors that affect the oxygen measurement, it is concluded what is the do's and don'ts in the process of measurement of the zirconium oxide oxygen measuring device.Zirconia sensor constant work temperature control is the key measurement technology for improving the accuracy of measurement.

The probe of zirconia measurement oxygen sensor is a kind of zirconia solid electrolyte (ZRO2 belongs to anionic solid electrolyte). At room temperature it is monoclinic crystal, when the temperature increases to 1150 degrees, the crystals translates into cubic crystal, while produce about 7% of the volume contraction. When the temperature falls, and become a monoclinic crystal.If the repeated heating and cooling, ZRO2 will break, so pure ZRO2 cannot serve as measuring element. If ZRO2 add a certain amount of yttrium oxide Y2O3 as stabilizing agent, after high temperature roasting, it will translate into stable zirconia materials.

Yttria Stabilized Zirconia(YSZ) oxygen measuring device is also called oxygen sensor, for the special appliacation ZRO2/Zirconia added Y2O3/Yttria is namely 8YSZ(stock#:U708) by HW NANO, the powder properties by shown the following table.

|

|

Size

|

BET

(m2/g)

|

ZrO2%

|

Y2O3%

|

Product Feature

|

|

U708:8YSZ

|

0.3-0.5um

60-80nm

|

10-20

|

86.4

|

13.3+_0.3

|

1. Jet and prilled powder are both available;

2. Specific surface and particle size can be controlled as needed;

3. Capacity for 60tons per month

4.Competitive price, especially in bulk

5. Good quality and public praise.

|

If you have any questions, please feel free to contact us at hwnano@xuzhounano.com. thank you.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917