100nm 99.9% BaTiO3 nanopowders for PTC thermistors

|

product name

|

BaTiO3 nanopowders

|

|

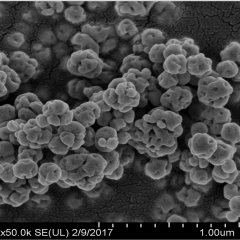

particle size

|

100nm

|

|

purity

|

99.9%

|

|

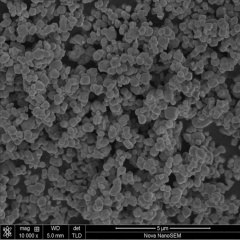

morphology

|

near spherical

|

|

crystal type

|

cubic type

|

|

appearance

|

white powder

|

|

MOQ

|

1kg

|

|

package

|

1kg/bag in double anti-static bags, 25kg/drum

|

BATIO3 belongs to the perovskite structure (ABO :) material, which has a centripetal resistance of the 10th to 10 squares with a batio3 ceramic material with a room temperature of 10 to 10. In 1950, HAAYMAN and others discovered that the trace amount of rare earth elements were added to the Batio3 ceramic material. The room temperature resistance rate will decrease significantly and become semiconductor ceramics and when the temperature rises to its centers TC = 120 ° C, its resistance rate rises sharply, and this feature is called PTC (POSITI Ve Temperator Coefficient effect.

PTC thermal resistance ceramic is usually based on titanic acid (BATIO3) or tritenuxide two -two (V2O3) ceramic material.

sex. Based on BATIO3 thermist ceramics, a small amount of rare earth oxides are usually mixed with a small amount of rare earth oxides as the owner of the BATIO3 base thermal sensitivity ceramics. In order to improve the PTC effect of thermist -sensitive ceramics

In response, manganese ions are usually added to the BATIO3 substrate material, manganese ions, grain size inhibitors (such as calcium ions), liquid -phase fever [such as tritenuxide (Al2O3), dioxide

Silicon (SiO2), titanium dioxide (TIO2)], can also change its lubine temperature by adding 锶 (SR), tin (SN), lead (PB) to Batio3 substrate materials.

For the research on the mechanism of the PTC effect, Haiwang and others proposed that the PTC effect is the weak model of the Haiwang model from the Schottki Blood of the polycrystal semi -porcelain crystal world. Two parts formed). The main performance parameters of PTC thermistor resistance ceramics are closely related to its application. Usually, the resistance temperature characteristics, current-time characteristics, and static Vodiatity of PTC thermistor resistance ceramics are usually based on PTC thermistor ceramics. PTC thermal resistance ceramics are widely used, such as making temperature sensors, overheating or overcurrent protectors, no contact switches, fixed temperature heating: device, etc.

Titanic acid pyrite PTC thermistor ceramic ceramics, with its relatively low cost, high mechanical strength, excellent anti -aging performance, and significant PTC effects, it has been widely used in various types of protection circuits and heating components in industrial and civilian.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917