Molybdenum Nanoparticles 70nm 99.9% Mo powder CAS 7439-98-7

Details:

|

MF

|

Mo

|

|

CAS No.

|

7439-98-7

|

|

EINECS No.

|

231-107-2

|

|

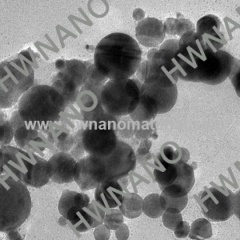

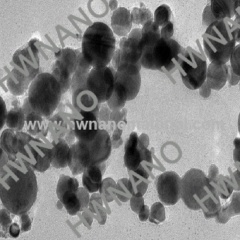

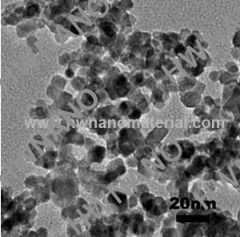

Size

|

70nm

|

|

Purity

|

99.9%

|

|

Appearance

|

Black Solod Powder

|

|

Other particle size

|

40nm, 100nm, 130nm, 2um

|

|

Brand

|

HW

|

Properties of Molybdenum Nanoparticles :

Nanofenal powder is larger than the surface area, with high sintering activity, high -temperature strength and high temperature hardness, good thermal conductivity, conductive performance, and good corrosion resistance.

Applications of Molybdenum Nanoparticles :

Alloy field

The consumption of molybdenum in the field of steel is very large, mainly used for production alloy steel (about 43%of the total consumption of molybdenum), stainless steel (about 23%), tool steel and high -speed steel (about 8%), cast iron cast iron He Roll (about 6%). Most of the molybdenum is used for steelmaking or cast iron after industrial oxidation blocks, and a small part is melted into molybdenum and then used for steelmaking.

The alloy element of molybdenum as steel has the following advantages:

Increase the strength and toughness of steel;

Improve the corrosion resistance of steel in the acid -base solution and liquid metal;

Improve the wear resistance of steel;

Improve the hardening, weldability and heat resistance of steel.

For example, stainless steels with a molybdenum content of 4%-5%are often used in places where erosion and corrosion such as marine equipment and chemical equipment are more serious.

The application of molybdenum copper alloy to the aerospace field to add other elements (such as titanium, titanium, tung, tungsten, and rare earth elements, etc.) with molybdenum. It can also form a stable, scattered distributed carbide phase to improve the strength of the alloy and the crystallization temperature. The molybdenum alloy is used for high -strength, mechanical stability, and high ductility because of its good strength, mechanical stability, and high ductility.

Package and storage of Molybdenum Nanoparticles

This product is packed in the laziness plastic bag. It is sealed in a dry and cool environment. It is not advisable to expose the air. Oxidation and reunion of the moisture prevention will affect the decentralized performance and use effect.

About Us:

Our Molybdenum Nanoparticles are in good quantity and competitive price

& available in a wide range of quantities and specifications to meet your

particular industrial or scientific application. For further technical information or pricing on Molybdenum Nanoparticles, pls contact us at: hwnano@xuzhounano.com.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917