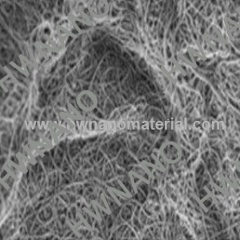

Buy Nickle coated MWCNTs Ni functioned carbon nanotubes

Surface modification of carbon nanotubes is actually the use of physical and chemical methods to change the status and structure of the carbon nanotube surface, the surface of the carbon nanotubes to achieve control, to change or improve the dispersion of carbon nanotubes to improve its surface activity, so that the surface of the new features, and to improve the compatibility of carbon nanotubes and other materials, the surface to generate new features, and to improve the compatibility of carbon nanotubes and other substances. After the Ni-coated carbon nanotubes surface activation energy is greatly reduced, making it not only the dispersion and get compatibility with other metals or compounds to improve, but also for the preparation of a one-dimensional magnetic nanowires and excellent performance of the two-dimensional, three-dimensional composites show a bright future.

Ni itself is a strong catalytic properties of metal self, thereby causing a strong catalytic role in the activation region from carbon nanotubes, grain growth in the direction of normal and tangential, to contribute to the growth of carbon nanotubes tangential surface the non-activated area coverage Ni layer growth method to reflect the direction of coating thickness growth rate, as the reaction can get continuous, uniform coating on the surface of carbon nanotubes.

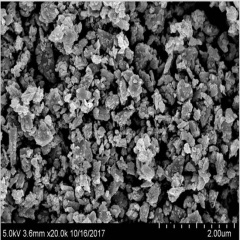

Carbon nanotubes can be used for material enhancement, electrical conductivity and other functional addition phases to prepare composite materials with better performance, but the interface bonding strength between carbon nanotubes and metal substrates is generally not high.

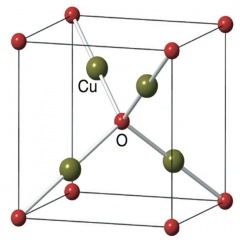

affects the strength of the composite material. Interfacial structure energy and original energy of nickel-plated carbon nanotubes and magnesium

The binding energy of the nanotubes is lower than that of the carbon nanotubes without nickel plating. The interface structure of the nanotubes after nickel plating is stable and the interface bonding strength is high.

Ni-coated MWCNTs can be aligned along the direction of the magnetic field within the matrix which provided a better reinforcing efficiency. Also, Ni-coated MWCNTs can be made to form a better bonding between the iron particles and the matrix.

We could do Ni-coated SWCNTs, Ni-coated DWCNTs, Ni-coated MWCNTs, any interested, kindly contact us freely.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917