CNT powders high quality for PET conductive masterbatch

1. CNT specifications we have

|

SWCNT-S

|

D: 2nm, L:1-2um,91% ( 95%, 99% also available)

|

SWCNT-L

|

D: 2nm, L:5-20um,91% ( 95%, 99% also available)

|

|

DWCNT-S

|

D: 2-5nm, L:1-2um,91%

|

|

DWCNT-L

|

D: 2-5nm, L:5-20um,91%

|

|

MWCNT-S-1

|

D: 10-30nm, L: 1-2um, 99%

|

MWCNT-S-2

|

D: 30-60nm, L: 1-2um, 99%

|

MWCNT-S-3

|

D: 60-100nm, L: 1-2um, 99%

|

MWCNT-L-1

|

D: 10-30nm, L: 5-20um, 99%

|

MWCNT-L-2

|

D: 30-60nm, L: 5-20um, 99%

|

MWCNT-L-3

|

D: 60-100nm, L: 5-20um, 99%

|

2. Application of CNT for conductive PET masterbatch

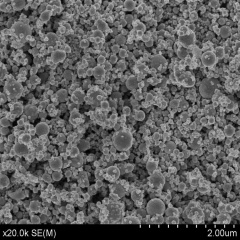

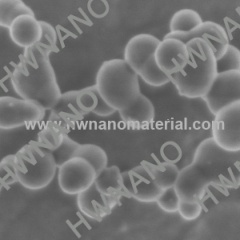

The carbon nanotuba belongs to a one -dimensional carbon nanoma, that is, a small tube shape with a diameter of nano -level. It has good conductivity, high thermal conductivity, chemical stability, and thermal stability. Due to its small density and large diameter ratio, carbon nanotubes have become a good polymer composite material conductive filler. Polymer materials are usually high in resistance. Long -term use will cause a large amount of static electricity to generate polymer products, which may damage the product, and there is still a harm to the fire and explosion. To solve this problem, it is a common solution to add conductive/antistatic parent particles to polymer materials.

Generally, there are two major categories of carbon nanotimal tube polymer composite conductive materials. One is to mix polymer materials and carbon nanotubes with dual screw or dense refining machines. The second is to dissolve the polymer material in the solvent, add the carbon nanotubes for mechanical stirring or ultrasound to disperse, and then remove the solvents to remove the electric conductivity.

PET is a common polymer composite material, there are PET conductive masterbatch on market that's prepared by carbon nanotubes added as conductive agent on the market.

3. RFQ

1. What's the package?

Double anti-static bags, for MWCNT 100g, 500g, ect; for SWCNT, DWCNT, smallest package is 1g.

2. If order what shipping will you use?

Usually Fedex, for some special country usually Special line, like Korea special line, Russia special line, etc.

3. May I pay the goods and arrange shipping with my own resources?

Yes, it is OK, but noted in China powders are sensitive goods, certain reports are needed, usually we let professinal chemial goods forwarder to arrange shipping, you need to make sure your resource can arrange chemical goods.

English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português 日本語

日本語 한국의

한국의 Türkçe

Türkçe

8620-87226359,8620-87748917

8620-87226359,8620-87748917